Robotics, once largely confined to performing repetitive, pre-programmed tasks in controlled industrial environments, is undergoing a profound transformation. This revolution is largely driven by the symbiotic integration of Artificial Intelligence (AI) into robotic systems. AI is fundamentally reshaping the capabilities of robots, imbuing them with the ability to perceive, reason, learn, and adapt to dynamic and unpredictable environments. No longer mere automatons, AI-powered robots are becoming intelligent agents capable of performing complex tasks with unprecedented precision, flexibility, and autonomy. This convergence of engineering robotics with sophisticated AI is not only redefining industrial automation but is also paving the way for robots to integrate seamlessly into various aspects of daily life, promising a future where intelligent machines work alongside humans to enhance efficiency, safety, and productivity across diverse sectors.

Read Also: Strategic Talent Development: Fueling Business Growth with Targeted Training & Upskilling

From Pre-programmed to Intelligent Autonomy

Traditional robots, while efficient at repetitive actions, operate on strictly pre-programmed instructions. Their functionality is limited to specific, predictable environments, and they often struggle with even minor variations or unexpected obstacles. The integration of AI, particularly through techniques like machine learning (ML), deep learning (DL), and computer vision (CV), has dramatically enhanced robotic autonomy and decision-making capabilities. AI serves as the “brain” for these machines, enabling them to move beyond rigid programming.

Photo Credit: Unsplash.com

AI-driven robots can now analyze sensor data in real-time, interpret their surroundings, and make independent decisions without constant human intervention. For instance, in manufacturing, an AI-powered robotic arm can adapt its grip or trajectory to pick up objects that are slightly out of place, or identify and sort defective items based on visual inspection. Autonomous Mobile Robots (AMRs) use AI algorithms to navigate complex warehouse environments, dynamically adjusting their routes to avoid obstacles, congestion, or even collaborating with other robots. This capability for learning and adaptation means that AI robots can continuously improve their performance over time, refining their actions based on experience and data. This shift from static, rule-based operation to dynamic, intelligent autonomy is a cornerstone of the future of automation, making robots more versatile and capable in a wide range of applications, from logistics and healthcare to agriculture.

Enhanced Perception, Interaction, and Collaboration

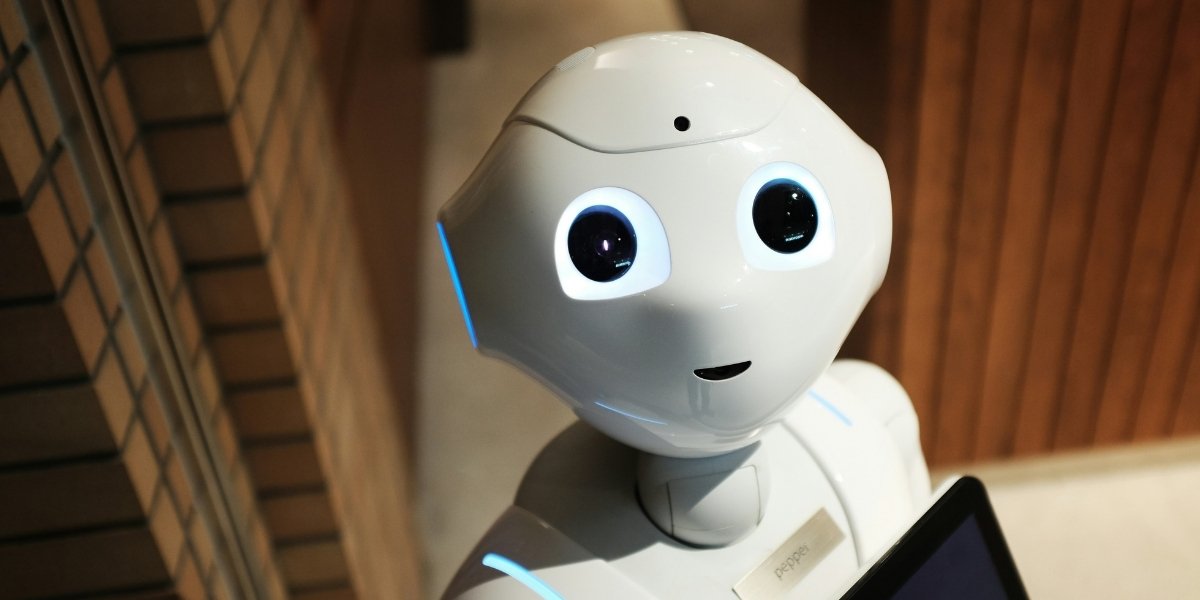

One of the most significant impacts of AI on robotics engineering is the dramatic enhancement of perception and interaction. Traditional robots had limited “senses,” often relying on basic sensors to detect proximity. AI, however, leverages advanced sensor fusion, computer vision, and even natural language processing (NLP) to give robots a much richer understanding of their environment and the ability to interact more naturally with humans.

Robots equipped with AI-powered computer vision can “see” and interpret their surroundings with high fidelity. This allows them to recognize objects, gauge distances, detect subtle defects on an assembly line, or even understand human gestures. In healthcare, AI-powered service robots can identify patients, comprehend spoken instructions, and potentially detect human emotions through facial expressions and tone of voice, facilitating more empathetic interactions. The development of collaborative robots, or “cobots,” is a direct result of these advancements. Cobots are designed to work safely alongside human co-workers, sharing workspaces without the need for traditional safety cages. AI algorithms enable them to perceive human presence, predict movements, and adjust their operations to avoid collisions, thereby improving workplace safety and productivity by allowing humans to focus on more complex, cognitive tasks while robots handle repetitive or hazardous ones. This elevated level of perception and sophisticated interaction is fundamental to expanding the roles of robots beyond isolated factory floors into shared human environments.

Optimizing Efficiency, Quality, and Predictive Maintenance

The integration of AI significantly boosts the efficiency and quality of automated processes. AI algorithms can analyze vast amounts of data from robotic operations, identifying patterns and optimizing workflows in ways that human analysis often cannot. In manufacturing, for example, AI-powered robots can refine their movements to reduce material waste, accelerate throughput, and maintain near-perfect consistency in production, leading to higher product quality and fewer defects. This precision translates directly into cost savings by minimizing errors and rework.

AI is revolutionizing predictive maintenance in robotics and industrial automation. By continuously analyzing sensor data from machinery—such as vibrations, temperature fluctuations, and performance metrics—AI systems can detect subtle signs of wear and tear or impending failures long before they occur. This allows manufacturers to schedule maintenance proactively, preventing costly unscheduled downtime and extending the lifespan of expensive equipment. Instead of reactive repairs, AI enables a predictive approach, ensuring that production lines remain operational and efficient. Companies utilizing AI for predictive maintenance have reported significant reductions in downtime and maintenance costs. This optimization driven by AI not only enhances operational efficiency but also contributes to greater safety by anticipating and mitigating potential mechanical failures, making AI an indispensable tool for maximizing the performance and longevity of robotic systems in demanding industrial environments.

Photo Credit: Unsplash.com

The Future of Automation: Human-Robot Collaboration and New Frontiers

The future of automation, powered by the ongoing advancements in AI and robotics engineering, envisions a landscape of increasingly sophisticated and pervasive intelligent machines. One of the most exciting trends is the deepening of human-robot collaboration. Beyond current cobots, future systems will likely feature more intuitive human-robot interfaces, leveraging generative AI and advanced NLP to enable seamless communication and shared problem-solving. This means robots will not just work alongside humans, but will actively learn from them, understand complex verbal commands, and anticipate human needs, transforming workplaces into more synergistic environments.

Read Also: Bridging the Education-Workforce Gap Through STEM

Emerging trends point towards robots with enhanced dexterity and agility, capable of performing intricate tasks like surgery with unmatched precision or handling delicate components in advanced electronics manufacturing. AI-powered humanoid robots, designed to mimic human form and movement, hold promise for general-purpose tasks in diverse settings, from assisting the elderly in homes to performing complex logistics operations in warehouses. The concept of “Physical AI,” where robots train themselves in virtual environments before deployment, and “Embodied AI,” combining perception, reasoning, and movement, are pushing the boundaries of what autonomous systems can achieve. Beyond industry, AI-powered robots are poised to make significant impacts in new frontiers: disaster management (navigating hazardous zones to locate survivors), space exploration (building habitats and gathering data on other planets), and personalized service roles. While challenges around ethics, safety, and job displacement remain important considerations, the trajectory of engineering robotics with AI is undeniably toward a future where intelligent automation plays an ever-expanding and transformative role across society, making processes smarter, safer, and more productive.