As a vital contributor to global economic development, the manufacturing industry is undergoing rapid transformations driven by technological advancements and evolving market demands. This article explores key challenges and growth opportunities, highlighting the manufacturing sector’s strategic focus on innovation and resilience.

Integrating Advanced Technologies for Competitive Advantage

Manufacturers increasingly turn to automation, artificial intelligence (AI), and robotics to enhance efficiency and competitiveness. However, adapting to these cutting-edge technologies requires careful planning to avoid disruptions to processes and the workforce. For example, while automation can streamline production, manufacturers must implement training programs to help employees effectively work with new technologies. This balanced approach supports innovation and aligns with ethical standards by promoting workforce inclusion and development.

Adapting technology in manufacturing is a long-term process with varied outcomes. While some companies experience immediate improvements, others may see incremental gains. Manufacturers should set realistic expectations about the time and investment needed to fully realize these benefits, recognizing that outcomes will differ depending on each organization’s unique challenges and capabilities.

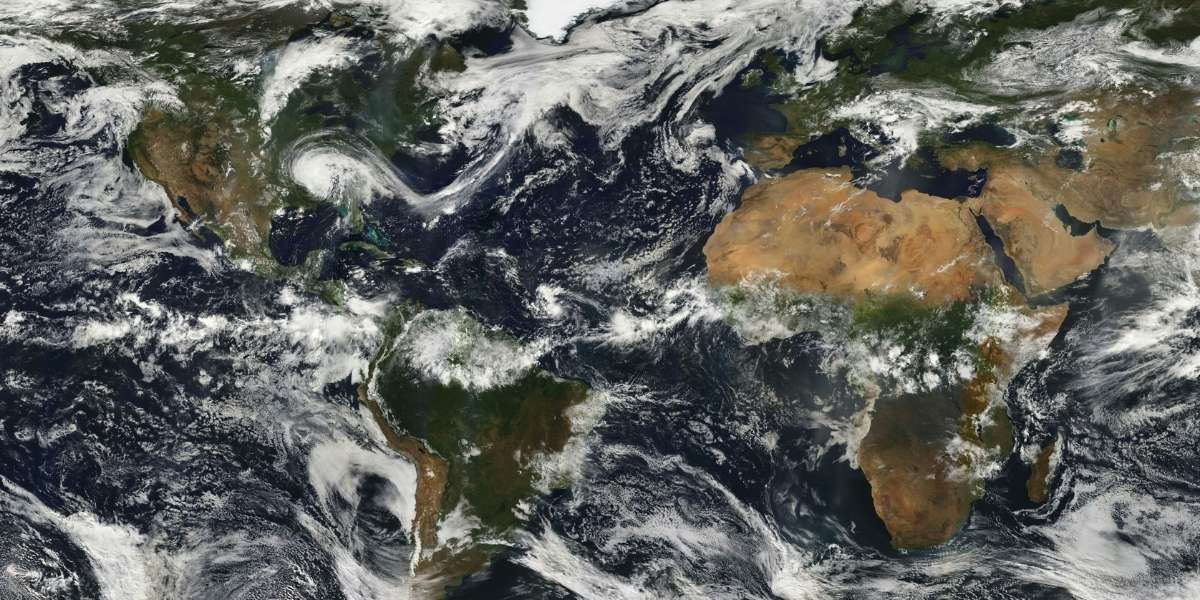

Addressing Supply Chain Vulnerabilities in a Global Market

Recent global events have underscored the importance of resilient supply chains, particularly for industries heavily reliant on international suppliers. Geopolitical tensions, natural disasters, and pandemics can all disrupt supply chains, posing significant risks. Many companies are diversifying suppliers, enhancing domestic production, or exploring local sourcing to mitigate these challenges as part of risk management. Implementing such strategies helps companies avoid single points of failure, ensuring a more stable supply of essential materials.

To promote transparency, manufacturers should communicate realistic expectations about supply chain stability to stakeholders. Instead of suggesting that supply chain adjustments will solve all issues immediately, manufacturers should emphasize ongoing efforts to enhance resilience and continuity.

Commitment to Environmental Sustainability

Sustainability is becoming a cornerstone of manufacturing, with growing pressure from regulatory bodies and consumers to adopt environmentally responsible practices. By reducing waste, conserving energy, and minimizing emissions, manufacturers comply with regulations and contribute to a healthier planet. Eco-friendly initiatives may range from using recycled materials to adopting renewable energy sources.

Claims about environmental impact should be grounded in verifiable actions rather than vague promises. For example, manufacturers can specify, “Our facility has reduced emissions by 30% over the past three years by implementing new energy-efficient systems,” rather than broadly claiming to be “environmentally friendly.” This approach provides transparency and aligns with FTC guidelines on truthful claims.

Bridging the Skilled Workforce Gap

A shortage of skilled labor continues to challenge the manufacturing industry. Many sectors need more skills and those available in the workforce, impacting productivity and innovation. Manufacturers are partnering with educational institutions to bridge this gap and develop specialized training programs. These collaborations provide students with hands-on experience, preparing them to meet the industry’s needs.

Workforce-related claims should focus on realistic outcomes of training initiatives rather than promising employment or success. For instance, instead of stating, “Graduates are job placement,” manufacturers can explain, “Our partnership programs help equip graduates with skills sought after in the industry, increasing their employment prospects.” This aligns with FTC recommendations to avoid misleading.

Harnessing the Power of Digital Transformation

The digital transformation wave, often called Industry 4.0, brings exciting opportunities for manufacturers to optimize operations. Technologies like the Internet of Things (IoT) and data analytics can enhance efficiency, reduce operational costs, and support product innovation. However, implementing digital transformation requires significant upfront investment and strategic planning, and results will vary.

Manufacturers should avoid implying instant success or results when discussing digital transformation. A compliant statement would be, “Digital tools like IoT and analytics help identify efficiencies over time, contributing to gradual improvements in productivity.” This wording maintains transparency and avoids creating unrealistic expectations about the immediacy or extent of results.

Expanding into the Global Market with Strategic Precision

Global market expansion presents manufacturers with new avenues for growth. Strategic collaborations, trade agreements, and entry into emerging markets can help diversify revenue streams. However, international expansion requires navigating complex regulatory environments and understanding local cultural nuances.

To ensure clarity, manufacturers should be transparent about the challenges of international expansion, such as regulatory compliance and local competition. Rather than implying that expansion will succeed, manufacturers could state, “Expanding into international markets provides growth opportunities, though results vary based on regulatory environments

Lean and Agile Manufacturing for Greater Flexibility

To thrive in a fast-paced environment, manufacturers increasingly adopt lean and agile principles, emphasizing flexibility, waste reduction, and responsiveness to change. Lean manufacturing minimizes waste, while agility allows quick adaptation to market shifts. Together, these principles help manufacturers remain competitive in an unpredictable landscape.

Promoting these approaches should avoid implying they will always yield positive results. A compliant statement might say, “By adopting lean and agile practices, we aim to improve efficiency and responsiveness, though results may vary depending on specific operational needs.” This phrasing acknowledges that while these practices are beneficial, their impact is not.

A Path Toward Sustainable Success

The manufacturing industry’s journey through technological advancement, supply chain transformation, and workforce development reflects a commitment to progress and resilience. By approaching these areas with a realistic and transparent mindset, manufacturers can build a foundation for sustainable growth. Emphasizing the unique aspects of each challenge and opportunity helps manufacturers set realistic expectations, fostering a balanced path to future success.

Published by: Nelly Chavez